FAQs

Have you ever had a question and either didn’t know where to find the answer or were too afraid to ask? If so, you’ve come to the right place.

As the name would suggest, this section is a compilation of answers to the questions our clients commonly ask. Here you’ll find answers to common printing questions our clients ask. Just start by following one of the links below.

Hotspot Packaging FAQs

Below is a list of frequently asked questions to help you choose, design and customize your carton. If you have a question that’s not on this list, please feel free to contact us. We’re here to help.

DESIGN, ARTWORK & GRAPHICS

What file format should I be uploading to Hotspot Printing for best results?

Any non-photographic content (including graphics and text) should be uploaded as vector-based files to ensure lines are crisp and clear. Logos usually need to be separated from the background, resized, or otherwise manipulated. Vector images offer the most versatility for these purposes. Supported formats currently include .jpg, .png and pdf.

What resolution should I be uploading to Hotspot Printing for best results?

For optimal results, format logos and graphics to at least 300 dpi (dots per inch), with transparent backgrounds. This gives good, crisp graphics. Images taken from the internet won’t work as they are generally 72 dpi.

How should I format my text and line art for best results?

- We suggest that the text should be no smaller than 10 points. Regardless of how the text looks on screen, fonts smaller than 10 points don’t print well on corrugate.

- Use bold weights and colors for text. This is especially true if you are using italics or script fonts.

- All fonts should be embedded in the file.

- When using strokes or lines, make sure they’re no thinner than 1 point.

Any tips for optimal design, artwork, and graphics when using Designer?

- Maintain Symmetry in your packaging design. A subtle, yet critical design consideration, symmetry registers in the mind subconsciously. Design elements that aren’t displayed in a symmetrical fashion can look out of balance and detract from the final product.

- Zoom in on critical panels (Front, Back, Left, Right, Top and Bottom). Don’t be afraid to magnify these crucial areas in your artwork to make sure things are where you intend them to be.

- For best results, ensure fonts are embedded in your final designs.

- Watch for typos and spelling.

- Less is more. The most elegant, appealing custom box designs are usually quite minimalist.

- Keep pictures and graphics to a minimum. They should demonstrate what the product is or does in a very clear manner.

- Finally, get feedback from colleagues — they can be your best critics, and can give you ideas you had not even thought of.

How do I make sure the printed area on my customized packaging will appear exactly where I want it?

- A “bleed” is needed when ink will be printed to the edge of a box. Because boxes can shift up to 1/32″ when cutting, you need to extend the ink 1/8″ past the perimeter of the box. This will guard against a white line being unintentionally added to your printed box. Remember that registration isn’t 100% exact to the die line. It becomes more problematic across cut/score lines and any art that attempts to match exactly over folded panels or flaps. Because of the manufactured tolerance, take caution in trying to match art exactly over folded panels or flaps.

- Leave at least 1/4″ between graphics/pictures/text and the folds or edges of panels. Avoid having the graphics become part of the panel fold, or cut off at the edge of the box. Remember, the paper can move up to 1/32″ as it’s being cut into a box after printing.

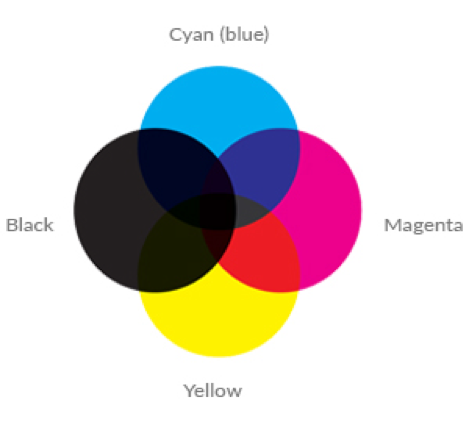

What color mode does Hotspot Printing accept?

Although you can upload artwork saved as either CMYK or RGB, we recommend converting your images into CMYK before uploading to Hotspot Printing. This is four color process printing or full color print. Using CMYK images will allow you to soft proof your images on screen, giving you a more accurate color representation. If you upload artwork as RGB, your artwork may appear duller or desaturated when printed.

Should my files be RGB or CYMK?

A good rule of thumb is anything dealing with the web should always be in RGB (Red, Green, Blue) and printed material should be in CYMK (Cyan, Magenta, Yellow, blacK). Â Print production usually requires the four-color process CMYK in high resolution of at least 300 dpi.

Our digital printing is done using CYMK, so if you upload your images in RGB we will automatically convert them to CYMK. This automatic conversion process can sometimes result in faded, dull or inaccurate color representation in the final printed project.

For the best printed color results, we strongly suggest converting your file format from RGB to CYMK before uploading. You can then adjust the colors after your conversion to appear more accurately to your intended result. Software programs, such as Adobe Photoshop, Adobe Illustrator and Adobe Acrobat have features to better represent CMYK colors on computer monitors. If you have one of these software programs installed on your computer, that should help you convert and preview the artwork.

To convert your image from RGB to CYMK:

Photoshop: open image > image > mode > CYMK color

Illustrator: open image > edit > edit colors > convert to CYMK

Acrobat Pro: open image > tools > print production > convert colors

How do I add a barcode to my custom packaging?

To scan properly, UPC barcodes need to be at least 2.2 inches wide. We recommend that barcodes be at least .5 inches tall for the best results. Barcode image files should be at least 300 dpi or uploaded as .ai, .eps, or .pdf files.

What part of the box can I customize?

All sides of the box are fully customizable — front, back, top, bottom, outside and inside. The inside can be printed for an additional charge. You can customize the outside only. You can customize both the outside and inside (even the flaps that tuck away or reside inside the folded box). You cannot customize the inside only.

Can I print on the inside of the box?

Yes, but there is an additional charge for printing on the inside of the box.

DIGITAL PRINTING AND FOLDING CARTONS

What material are the Folding Carton boxes?

Most folding carton boxes are made from 18pt – 24pt SBS paperboard.

Can I ship a folding carton box?

While they are superb choices for display and internal packaging of smaller items, they do not have the rigidity that is necessary to protect your items during shipping. We recommend placing them into a sturdy corrugated external box to protect your contents during shipping.

Can I get my Folding Carton boxes foil stamped or embossed?

Yes indeed. You will need to call us for a quote before you place your order.

What is your Folding Carton average turnaround times (excluding shipping)?

Fold Up Boxes, Gable Boxes, Pillow Packs, Tuck Boxes, Golf Sleeves = 7-10 business days

Hotspot Printing FAQs

At what resolution should I save my photos and graphics?

Resolution should be set to 300 dpi.

Pictures and graphics pulled from the internet are often low resolution, typically 72 dpi or 96 dpi. Avoid these graphics, as they will appear pixilated and blocky when printed.

Also note that you should save all photos in CMYK mode, not RGB mode when possible. Images saved in RGB mode may not print properly. If you are unable to save your image in CYMK mode, please let us know.

How do I go about getting an estimate from you?

Well, since you are here, we would suggest you use our online estimate request form. Otherwise, the best way to ensure that we get all the information necessary to do an accurate quote, give us a call and talk with one of our client service representatives.

How long does it take for you to complete my order?

Generally speaking, we typically turnaround projects in 5 to 10 working days from receipt of final approval. We also realize there are times when you need us to step it up and deliver your projects sooner. We will do our best to honor your requests for quicker delivery if it is in our power to do so. It is always best to check with us early on in the development of a project so that we may help complete your project on time and on budget.

Is white considered a printing color?

Not typically. Because white is the default color of paper, it is simply recognized as the absence of any ink. However, when using colored paper, white ink may be used if any text or graphic requires it.

What file format should I use when submitting my electronic document for printing?

PDF (Portable Document Format) is the most common and preferred file format for submitting digital documents. With the installation of a PDF print driver on your computer, virtually any program can generate a PDF file suitable for printing. Both commercial and free PDF print drivers are available online for download from different sources.

What is a proof and why is it important that I look at it?

In printing terms, a proof is a one-off copy of your document after all modifications and printing setup processes have been completed. It is your last and best opportunity to make sure that the print job comes out the way you want. By carefully inspecting the proof, you can help us assure an accurate, flawless delivery of your print job on the first run.

What is the Pantone Matching System?

The Pantone Matching System (PMS) is a color reproduction standard in which colors all across the spectrum are each identified by a unique, independent number. The use of PMS allows us to precisely match colors and maintain color consistency throughout the printing process.

What type of products and services do you provide?

Good question! We are a full service shop and offer a wide range of products and services. To see a full listing and description of what we can offer you, checkout the Products & Services pages of our website.

Why do the printed colors look different from the colors on my screen?

In short, printers and monitors produce colors in different ways.

Monitors use the RGB (red, green, blue) color model, which usually supports a wider spectrum of colors. Printers use the CMYK (cyan, magenta, yellow, black) color model, which can reproduce most—but not all—of the colors in the RGB color model. Depending on the equipment used, CMYK generally matches 85–90% of the colors in the RGB model.

When a color is selected from the RGB model that is out of the range of the CMYK model, the application chooses what it thinks is the closest color that will match. Programs like Adobe Photoshop will allow you to choose which color will be replaced. Others may not.